Contents:

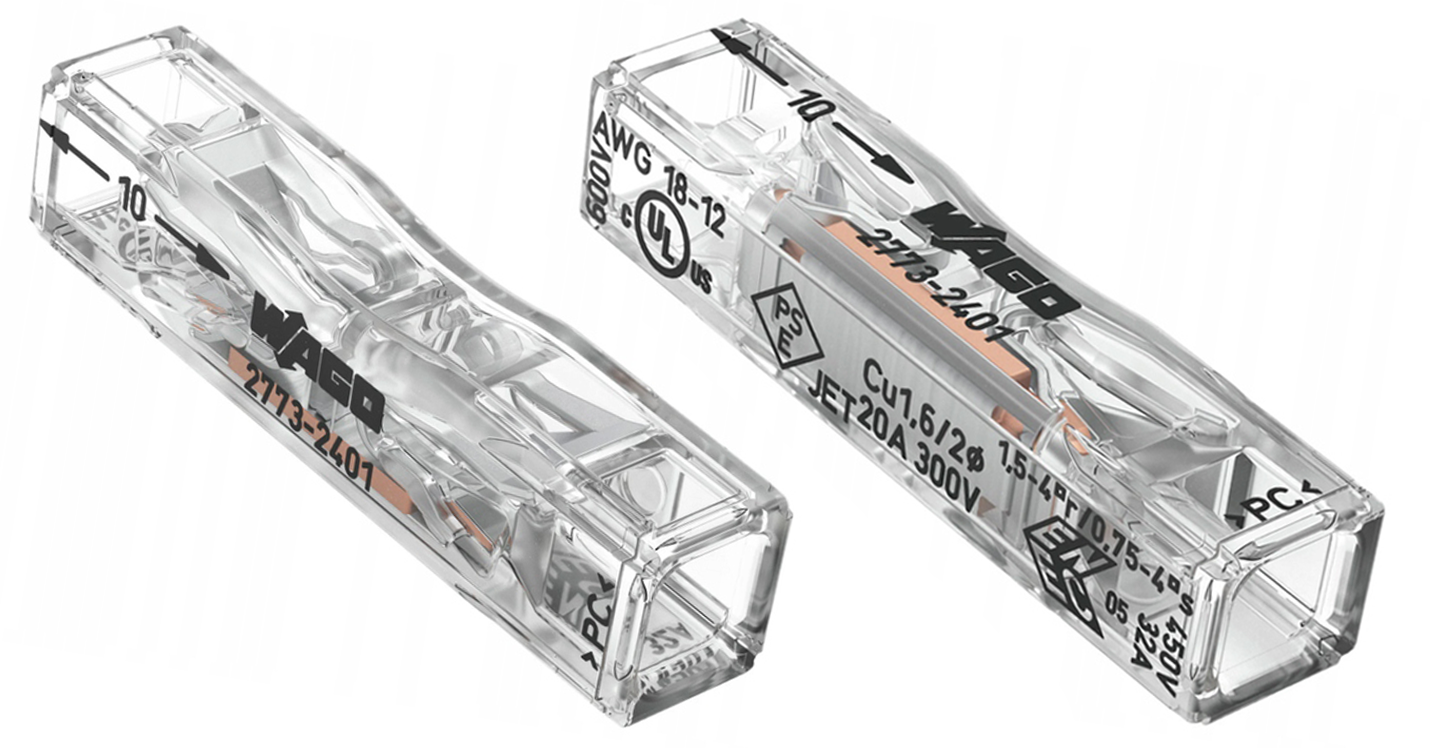

How can you repair damaged cables or extend them easily? The PUSH WIRE® Inline Splicing Connector, series 2773 from WAGO, will help you do just that.

The PUSH WIRE® Inline Splicing Connector, series 2773 can connect cables with cross-sections from 0.75 to 4 mm2 in very tight spaces and without using tools. Simply strip the conductor and insert it into the connector — a reliable connection is ready! And without any tools!

Advantages of the PUSH WIRE® Inline Splicing Connector, series 2773:

- provides fast and easy repair of damaged cables;

- simply insert solid and stranded cables into the connector without using any tools;

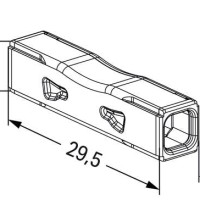

- connect conductors in confined spaces — thanks to the connector’s particularly compact design with a length of only 29 mm.

USE CASE EXAMPLES

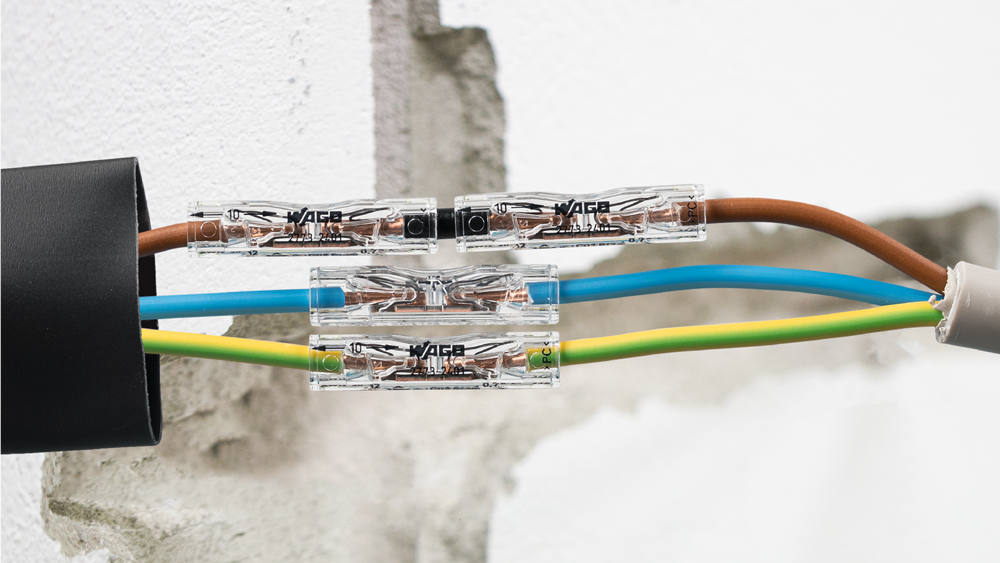

In a junction box

Thanks to its compact design with a length of only 29 mm, the PUSH WIRE® Inline Splicing Connector can be inserted into any junction box

This makes cable routing extremely convenient in confined spaces.

Need to extend a cable? The PUSH WIRE® Inline Splicing Connector helps you do it quickly and easily! The connector saves time and extends wires with cross-sections from 0.75 to 4 mm2 without any tools.

The WAGO PUSH WIRE® series 2773 connector is a fast troubleshooting solution for any situation. It can connect conductors from 0.75 to 4 mm2 in very tight spaces without any tools.

The PUSH WIRE® Inline Splicing Connector and heat-shrink tubing form the essential kit for quick cable repair.

Repairing a cable in a wall

On a busy day at a construction site, a cable may be damaged as a result of drilling. For the PUSH WIRE® series 2773 connector, this is not a problem, because it can be used for troubleshooting in any situation. A damaged cable can be repaired using heat-shrink tubing. This makes cable repair quite simple:

cut the cable and attach the connector.

Finally, slide the heat-shrink tubing over the newly connected cables and shrink it.

The cable is securely connected!

In hard-to-reach places

Modern construction places high demands on electrical connections, especially when it comes to ease of use, safety, reliability, and flexibility. Cable connections located in hard-to-reach places, for example in concealed junction boxes, often create problems for electricians. In such cases, regular inspection, maintenance, or repair is impossible. Therefore, all connections in hard-to-reach places must be made once and for all, without the possibility of modification. Previously, only soldered, crimped, or special sleeve connections were permitted in such locations, and their installation was complex, error-prone, and time-consuming.

The DIN VDE 0100-520:201306 standard, in force since 2013, stipulates that connecting elements that comply with current product standards may also be used in locations that become inaccessible after installation. All WAGO installation terminals meet the requirements of this standard, including the PUSH WIRE® Inline Splicing Connector, series 2773.