Contents:

- Why do professionals and hobbyists around the world value WAGO 221?

- One type of terminal for all types of cable

- With care for the future

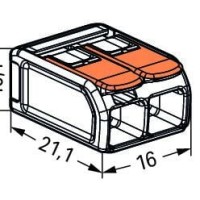

When WAGO began producing the 222 series installation connectors in 2004, they set completely new standards in terms of convenience and versatility. Just a few years after their launch, WAGO proved that even something excellent can still be improved.

The 221 series terminals, whose sales began in 2015, are the successor to the 222 series terminals, which are well known not only among professionals.

Why do professionals and hobbyists around the world value WAGO 221?

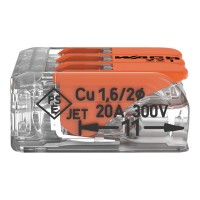

Like all WAGO installation terminals, the 221 series is also based on spring clamp technology, patented and continuously improved by WAGO. That is why the 221 terminal does not require any additional tools during installation.

The spring clamp provides not only convenience but also a longer service life of the connection. Unlike screw connections, the spring clamp is resistant to vibration, which is one of the main causes of connection failure in the long term.

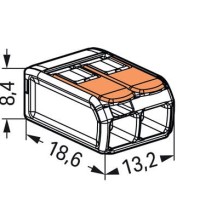

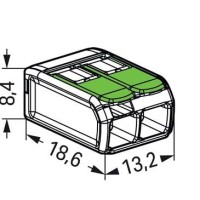

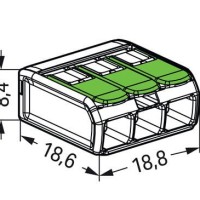

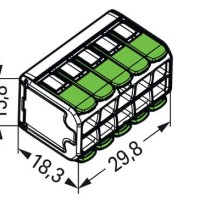

While keeping all the advantages of the previous model, the company managed to reduce the size of the new connector by 40%! Every electrician knows how important every extra millimeter is in a small junction box. The extremely compact size (8.3x18.6x18.7 mm in the 221-413 version) not only allows the connectors to be used in confined spaces, but also increases installation comfort and makes it easier to expand the installation.

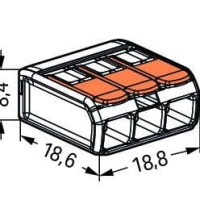

Another element that distinguishes the 221 series terminals is the transparent housing. Thanks to this, we always know whether the wires are positioned correctly in the terminal and whether they are stripped to the required length. Users will also appreciate the two test ports, which also

allow measurements to be taken with the wires connected.

The manufacturer has also significantly improved the operation of the clamp opening lever, which now requires less effort. Installation convenience is also increased thanks to the thickened side walls, which make it easier to hold the connector.

One type of terminal for all types of cable

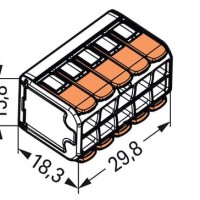

All 221 series terminals are suitable for installing solid conductors with a cross-section of 0.14…4 mm2 and stranded conductors with a cross-section of 0.2…4 mm2. This makes WAGO 221 suitable for connecting conductors of different types and cross-sections.

The terminals are rated for a maximum nominal current of 32 A/450 V and can be used at a long-term permissible temperature of 105°C. ENEC and UL certificates confirm that the 221 series is approved for use in global markets.

With care for the future

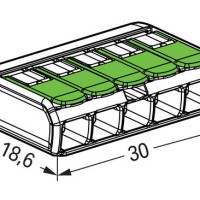

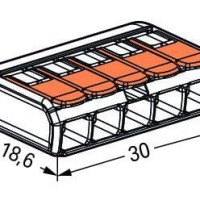

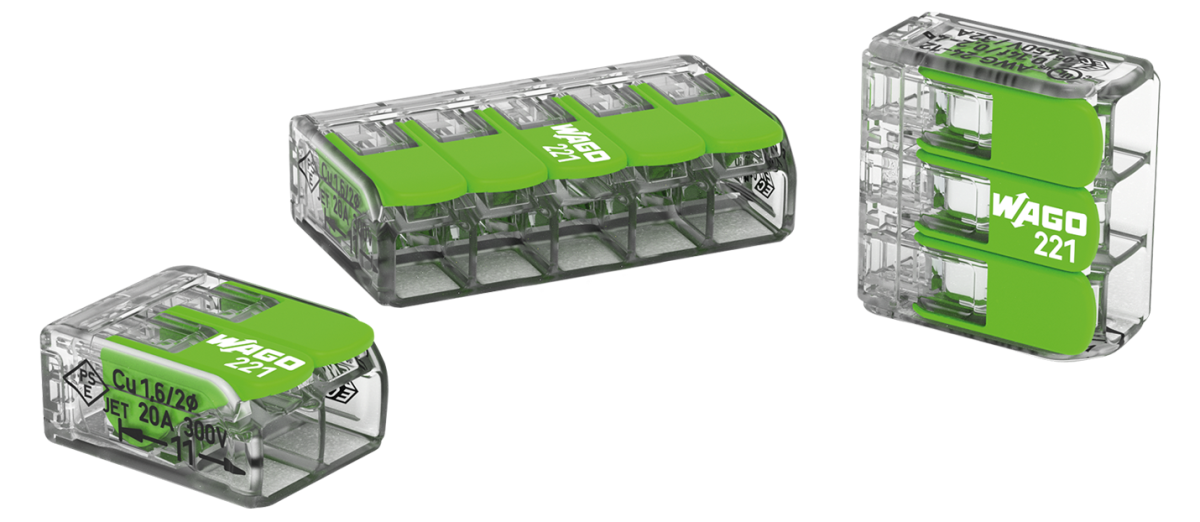

Green Range 221 is the first WAGO connector partially made from recycled plastics and bio-based materials.

When it comes to the fate of our planet, every little detail matters. That is why one of WAGO’s most recognizable products—the 221 series lever-operated installation terminal—is now available in an eco-friendly version. The new terminal is made largely from certified bio-based and recycled plastics. This solution makes it possible to use existing resources and prevents the creation of new waste. In this way, WAGO sets new standards in connection technology and takes responsibility for a more sustainable future—because every big change starts with a small step.

The new WAGO Green Range 221 terminal has the same advantages and characteristics as its predecessor with orange levers, but is made from more sustainable materials. As much as 77% of the polycarbonate (PC) used to create the housing comes from the processing of biological household waste and residues from industrial processes (for example, tall oil, used cooking oil, residues from vegetable oil production). The green levers, on the other hand, contain at least 27% polybutylene terephthalate (PBT) obtained from recycled raw materials (for example, recycled PET bottles). Thanks to these solutions, unnecessary waste becomes a valuable resource again.

Not only the terminal itself is made from eco-friendly raw materials, but also its packaging. Fibers from grass are used to produce this packaging, accounting for 30%, with the remaining materials made from recycled paper.

In the production of “grass paper”, compared to purely recycled paper, CO2 emissions are reduced by 5.6% and water consumption by approximately 11%. In addition, “grass paper” has a lower (by about 28%) impact on biodiversity. The grass used for its production comes from compensation areas designated for development or from uncultivated agricultural land that must be mowed as required.

Among the benefits, the following can be noted:

- the use of recycled plastics and bio-based materials in production;

- reduced consumption of fossil resources thanks to a closed-loop cycle;

- identical quality and certification as the classic 221 series connecting terminals.

For WAGO, this is very important, because we pay special attention to the types of materials used in production and the environmental footprint created in the process.

The new WAGO Green Range 221 terminal is an alternative for everyone who wants to connect in a more conscious and eco-friendly way.

WAGO 221 series terminals are not just ordinary connecting terminals. They are a symbol of innovation and efficiency in the field of electrical engineering. Ease of use, reliability, a wide range of applications, and time savings are the characteristics that make them the number one choice for professionals and enthusiasts. WAGO 221 is an innovation that is changing the game in the world of electrical connections.